Caring for the Motor and Motor Belt

On rare occasions the motor will become obstructed and jam, which is indicated by the motor humming when the run/start switch is pressed.

Motor Belt

If the motor belt is too loose, it can slip, causing the crankshaft to start slowly when turning. A belt that is too tight causes drag on the motor and may cause excessive bearing noise.

The motor can be turned manually by using either of the hand wheels located at the back and front of the machine. When standing at the back of the machine, the motor is turned forward by turning the back hand wheel in the counter clockwise direction. When standing at the front of the machine, the motor is turned forward by turning the front hand wheel in the clockwise direction.

Replacing the Motor Belt

Checking and Replacing the Motor Belt

Checking and Replacing the Motor Belt

Gammill recommends replacing your motor belt every five years or 500 quilts, whichever comes first. A worn belt will slip, and will be too loose. It can cause:

The needle to stop too close to the fabric.

Threads to get caught underneath when you try to pull up the bobbin.

The machine to take more than one stitch when you only asked for one, or take extra stitches after you stop the machine.

Long stitches or short stitches when coming in and out of points on a design.

Inaccurate Stitches Per Inch

To check and replace the motor belt:

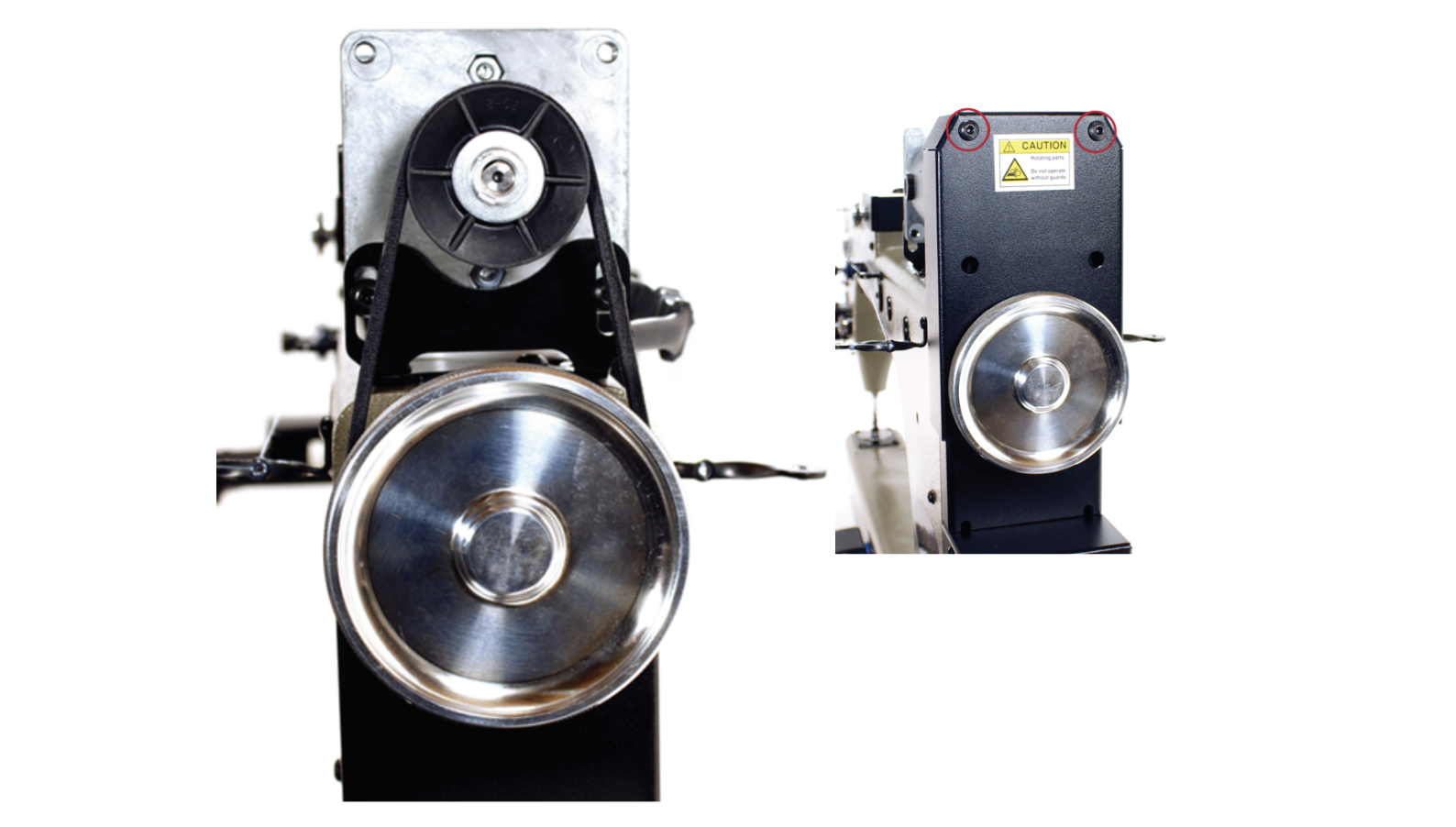

Remove the two screws holding the belt guard in place.

Remove the belt guard.

Look for worn (slick) areas on the inside of the belt, or fraying on the edges of the belt, look for black belt dust inside belt cover area.

To replace, remove the belt by pulling a portion of the belt over pulley and rotate the hand wheel.

Motor Jams

On rare occasions the motor will become obstructed and jam, which is indicated by the motor humming when the run/start switch is pressed. Most likely the jam is caused by a tiny piece of thread embedded between the hook race and the rotary hook. The motor hums but does not rotate. To clear the jam, turn off the stitching, go to the back of the machine and turn the hand wheel clockwise until the jam is released. This might take two hands and a much stronger force than normal to accomplish.

Tip: Strap can openers or oil filter wrenches work well for this operation.