Needles and Needle Bar

How to replace needles and make adjustments to stitching.Plus, how to remove the throat plate.

Recommended Needles

Gammill machines are designed to use standard length industrial machine needles in a variety of sizes.

At the factory, your machine is adjusted to sew with a 4.0 needle. The clearance to the hook tip varies with needle size, so the machines stitch best with 3.5, 4.0, 4.5.

- Use Groz-Beckert 134 MR (needle type) and R (sharp tip)

- Most longarm threads use 3.5 or 4.0

- Silk threads use 3.0 or 3.5

- Metallics use 4.5 or 5.0

A higher numbered needed has a thicker shaft, which will more easily penetrate thicker fabrics with less thread breaks.

Tip: It is recommended that the needle be changed after each quilt. The points become blunt with use and may cause damage to the fabric or result in poor stitch quality.

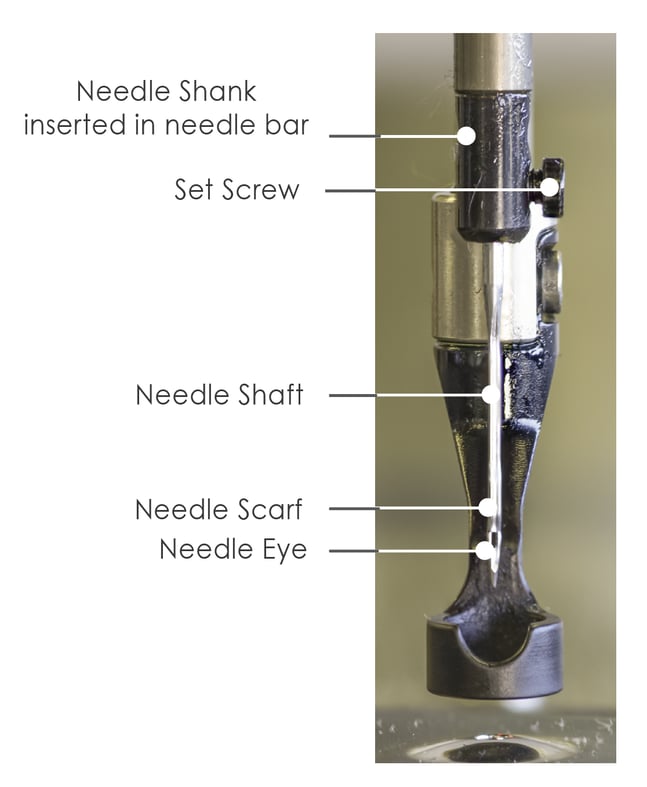

Parts of a Needle

The picture shows a properly inserted needle. The top part of the needle is called the shank. The shank is inserted into the needle bar and a set screw holds it in place. The area of the needle between the shank and the eye is called the shaft. There is a groove at the front of the needle that runs the length of the shaft and faces away from the machine. The grove provides a space for the thread on its way into the fabric layers. Without the groove, the thread would break as it enters the fabric. So, in addition to having the eye face toward the front of the machine, make sure the side with the groove is facing you, not the machine. The concave area in the back of the needle is called the scarf. The scarf faces the throat of the machine and provides a place for the thread to form a tiny loop as the needle is raised out of the fabric. The hook on the bobbin race takes this loop of top thread and loops it around the entire bobbin case to form the stitch.

Video | Replacing the Needle

|

Replacing the Needle Unlike home sewing machine needles, the shank of an industrial needle is round. There is no flat edge to ensure proper installation of the needle in the needle bar. Instead, you must check that the eye of the needle is facing straight toward the front of the machine. Note the long groove along the FRONT of the needle. Note the scarf (bump out) on the FRONT of the needle. Loosen the needle set screw and remove the old needle. Clean all lint out of the hole at the top of the needle. You can use canned air to blow lint out or insert the sharp end of the old needle to clean out the needle bar. Insert the needle shank into the needle bar making sure the needle is inserted as far as it can go. Rotate the needle so that the long thread groove is facing directly out to the front of the machine. A needle bar magnet can aid you. In most cases the best angle for your needle is such that your needle eye points at the onboard bobbin winder thread cone holder at the back of your machine. Carefully position the needle at an angle that you’ve chosen on purpose. Tighten the set screw. Tip: You don’t want the needle to be nearly or exactly the same angle as any line in your quilting pattern. A needle alignment magnet helps to get perfect stitches. |

|

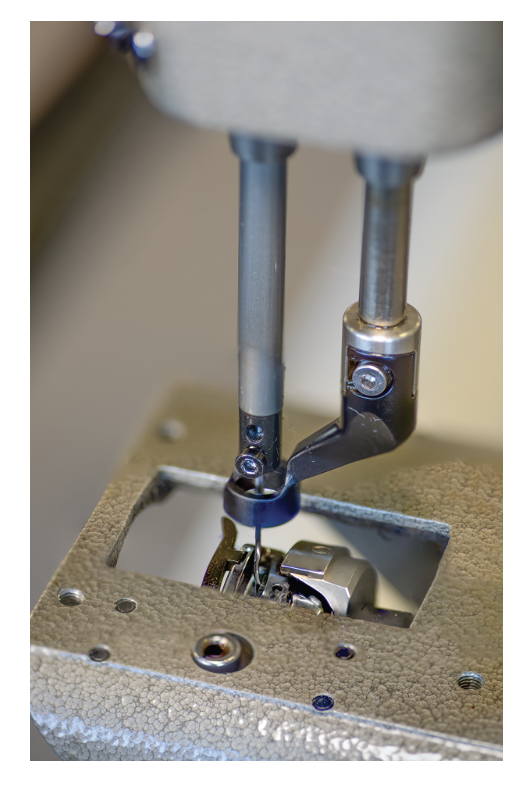

Parts of the Needle Area

Gammill quilting machine heads use industrial needles with round shafts. The needle carries the thread through the fabric. The needle bar holds the needle and maintains the needle height to create good stitches as it moves up and down to form the stitch. This bar can be adjusted up or down to the proper machine timing height.

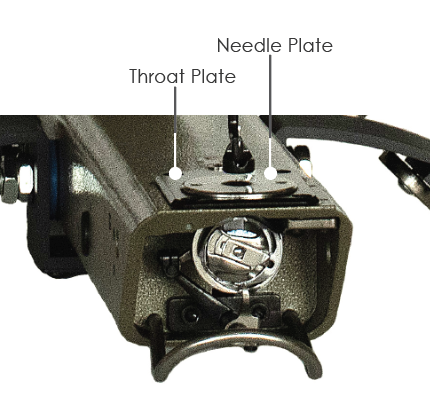

The round needle plate is attached to the top of the square throat plate. The small hole in the needle plate restricts the movement of the thread as the stitch is formed.

The presser bar holds the hopping foot and controls the height and stroke. The hopping foot rises and lowers with the movement of the needle to press and release the fabric as the stitch is formed. The hopping foot can be used with rulers and templates and its height and stroke can be adjusted for proper stitch formation.

Needle Bar

The needle bar holds the needle and provides the up and down motion during stitching. The needle bar should be stable with no side-to-side motion.

Needle Bar Stability

To check needle bar stability, first rotate the hand wheel until the needle bar is in its lowest position. Next, test for excessive side-to-side motion.

If significant motion exists it may indicate badly worn needle bar bushings and require their replacement. This needle bar bushing replacement should be done trained Gammill technician.

Adjusting the Needle Bar Height

|

First, check the needle bar height. Make sure the needle is inserted fully into the needle bar. Then, rotate the front hand wheel until the needle bar is in its lowest position. |

|

|

From underneath, looking straight at the sewing hook, 60 to 90 percent of the needle eye should be visible; however, none of the needle above the needle eye should be visible. If the needle bar is set too high or too low it can result in skipped stitches or excessive thread breaks. |

|

|

Remove the cover for the needle bar set screw. With the needle bar at its lowest position, loosen the set screw visible through the hole and raise or lower the needle bar until the nearly the full needle eye is visible. Make sure the needle bar has not pivoted from its original position; tighten the needle bar set screw securely. Note: On the Vision 2.0 18-8 the needle bar set screw is located behind the front handles. |

|

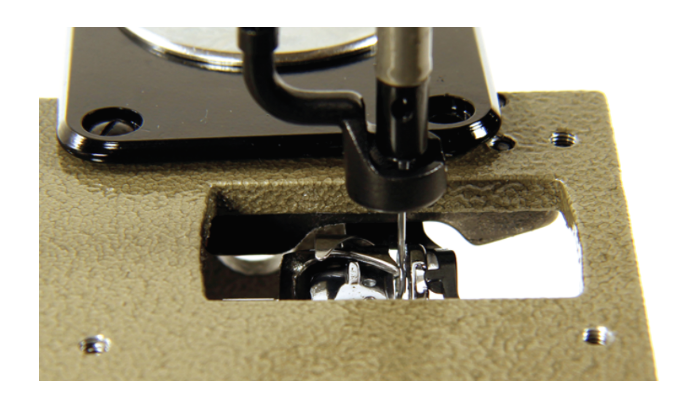

Needle Plate

The needle plate is the silver, circular disc attached to the top of the throat plate. The needle plate has a small hole to accommodate the needle moving in and out of the fabric. The hole helps to restrict side-to-side movement of the thread as the stitches are formed. The only time the needle plate should need to be removed is to inspect it for burrs or for cleaning.

As the needle moves at high speeds it is deflected. Most often this deflection does not cause problems, however if the sewing head is moved too quickly over the quilt or the fabric is too tight, needle deflection does not have sufficient time to recover. The deflected needle can strike the edges of the hole in the needle plate. This can cause thread breaks and/or burrs in the needle plate.

Removing the Throat Plate

The throat plate is the rectangular shaped, black plate affixed to the lower arm of the sewing head. The throat plate is moved out of the way or removed to gain access to the rotary hook assembly. It is not necessary to completely remove the throat plate. Instead, loosen and remove the two upper screws and one of the lower screws. Loosen the fourth screw. You can now rotate the throat plate out of the way to access the rotary hook assembly.

Note: Make sure to center the needle with the hole on the needle plate when reinstalling the throat plate.