Oiling Your Machine (Hand Guided)

The Gammill machine head is designed for many years of use with proper maintenance including regular cleaning and oiling.

Oiling 18-inch machine heads

In this video, we’ll show you how to oil your 18-8 machine, which is a slightly different process than oiling other sizes.

Oiling Schedule

The Gammill machine head is designed for many years of use with proper maintenance including regular cleaning and oiling. Since every machine is used differently, there are no standard rules for the frequency of oiling the machine or the amount of oil used each time. It is important that a small amount of oil is present in the oil ports at all time. However, too much oil may cause excess oil to seep from some part of the machine. Because of this, it is a good idea to park the machine away from the quilt when not in use and to wipe down the table and machine before loading, unloading or quilting the quilt.

Some indications of the need to oil the machine or bobbin are a change in sound as you quilt or a bobbin and/or bobbin case that is hot to the touch. Some general guidelines are listed below. Start with these guidelines in this chapter and adjust the frequency or amount of oiling as needed to fit your quilting schedule.

Oil the machine each day that you use it. It the machine has not been used for a few days it is recommended that you oil it the night before to allow the oil time to work its way through. If excessive oil drips from the bottom of the machine, then decrease the frequency of oiling.

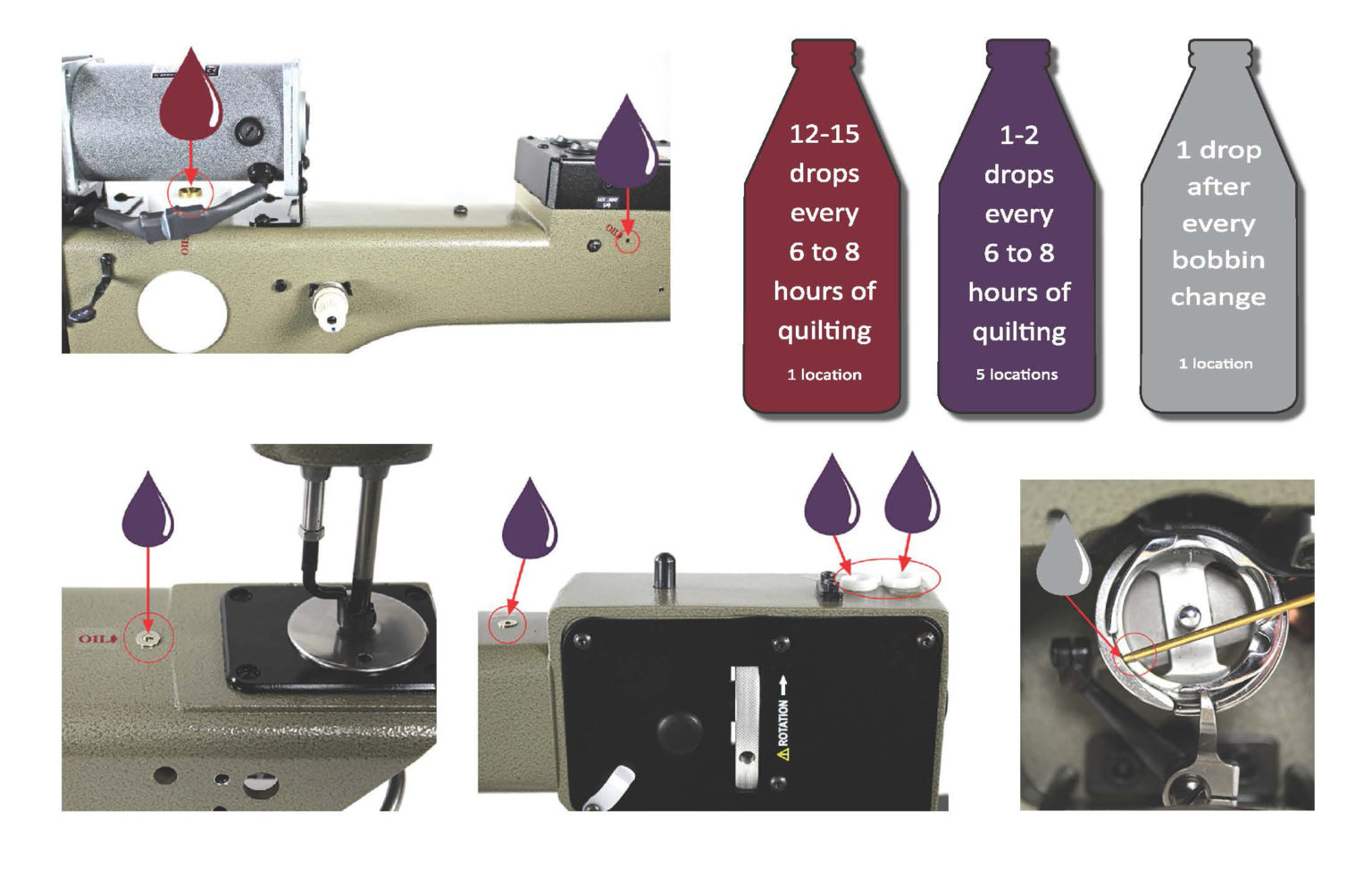

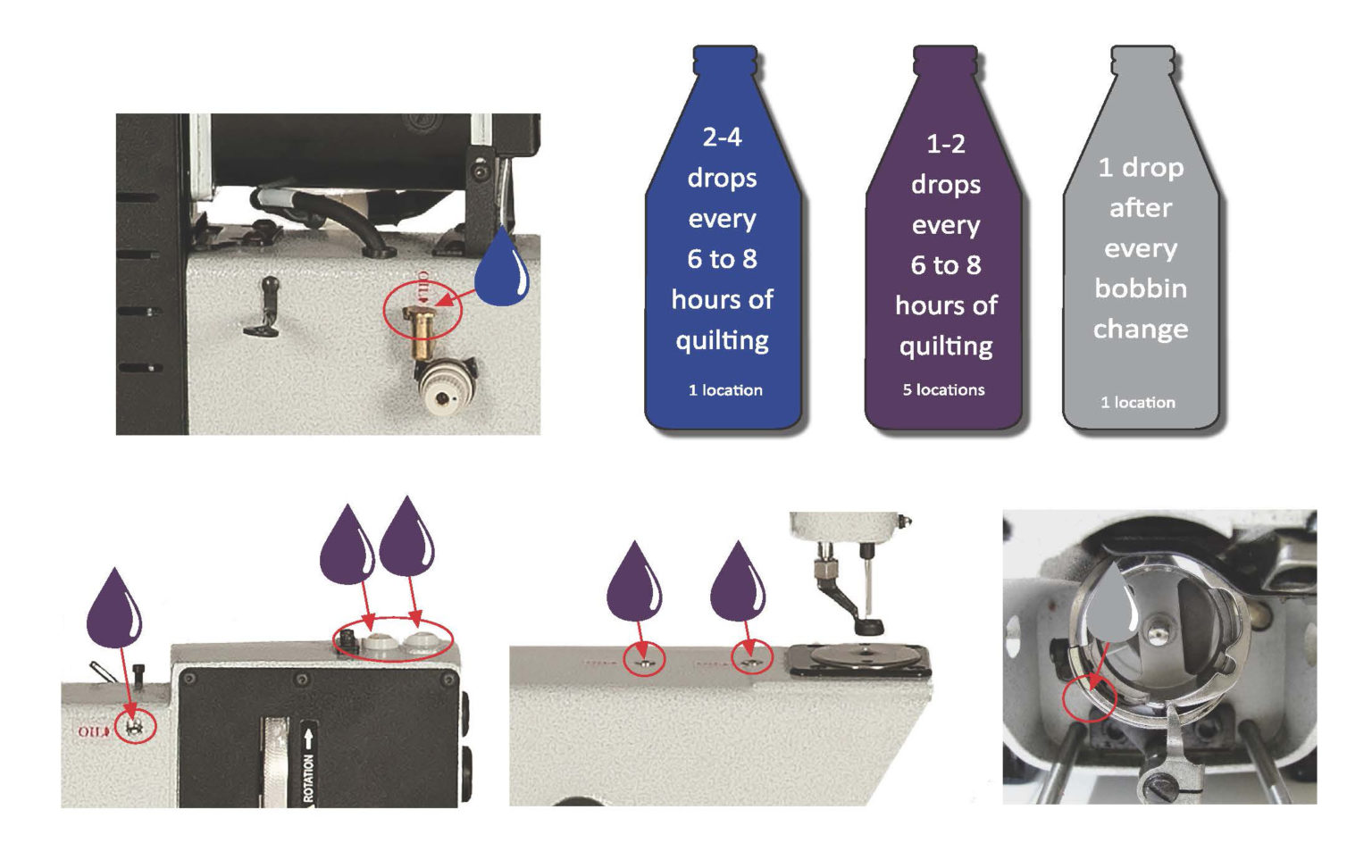

The graphics above show oiling locations for all models. Two of the oil ports are capped with stainless steel spheres. The container of oil included with your machine has a thin brass tube affixed to the mouth. Use this tube to push down on the sphere to direct the oil into the port.

Tip: oil the hook assembly each time you change the bobbin. Place the oil in the top of the three holes along the inside of the hook assembly. Let it run down into the other two holes. Rotate the hand wheel three turns to distribute the oil evenly.

Draining Excess Oil from the Take-Up Lever Box

Over oiling of the oil wicks located above the needle bar and presser bar causes oil to run down the needle bar or presser bar. To clean out the excess oil, first move the machine off the quilt and place a paper towel or other absorbent material under the drain hole to catch the excess oil.

Remove the

Type of Oil

Use only clear machine oil (not yellow oil). Yellow color indicates the presence of varnish that will build up on machine parts, causing friction as the machine sews. This friction reduces the useful life of the machine.

Oiling Tips

Gammill uses long-lasting, industrial-quality bushings to keep our machines running. As long as these bushings are kept properly oiled, they likely will never need replacement.

What Makes Gammill Oiling Superior?

Bushings can handle high loads and impacts much better than ball bearings. The engine in your car doesn’t use ball bearings for the crankshaft, camshaft, etc. for the same reason – they can’t handle the stresses and won’t have the life you expect. Would you want to rebuild the engine in your car every year? No – and we don’t expect you rebuild your quilting machine yearly either, so we use the most durable bearing option possible.

Gammill’s industrial quality bearings and bushings keep our machines running all day, every day for years. Most of Gammill’s original machines are still quilting out in the world today more than 35 years later. The Gammill has been proven to last for decades. Plus, Gammill machines do not have to be taken to a dealer for an annual oiling maintenance process. A few minutes of oiling each week saves you the time and expense of a visit to the dealership or service call.

How it Works

All Gammill needle bar, hopping foot, and shaft bushings are made of long-lasting steel. These industrial quality bushings require an oil film to maintain low friction and low wear on the bushings. This keeps the machine running efficiently and quietly. Each machine features an effective wick oiling system. The wicks are oiled through central oiling locations and as the bushings begin to warm, they pull more oil as needed.

Alternatives to Oil

Some other companies in the industry use “permanently” lubricated bushings. These are made of a softer material, such as bronze or brass, and are manufactured so that the oil is built in. These softer bushings have a limited lifespan and are normally designed for locations with limited movement. Forces and frictions that generate too much heat (which happen in fast-moving machinery like quilting machines) can cause the oil to evaporate out of the bushing. Even without a great deal of force or friction, oil can evaporate over time. If the bushing loses its lubrication it must be replaced.

How Long Does Oiling Take?

Oiling a Gammill is a quick and easy process! Once you become accustomed to the process, oiling a Gammill machine can take less than a minute.

Under Oiling

Some indications of the need to oil the machine or hook are a change in sound as you quilt or a bobbin and/or bobbin case that is hot to the touch. Other indicators could be that the machine is now tighter than it was before. If you experience any of these issues or other concerns, please contact Gammill for assistance.