Parts of the Machine Head (Hand Guided and Elevate)

Learn the parts of your Gammill Machine.

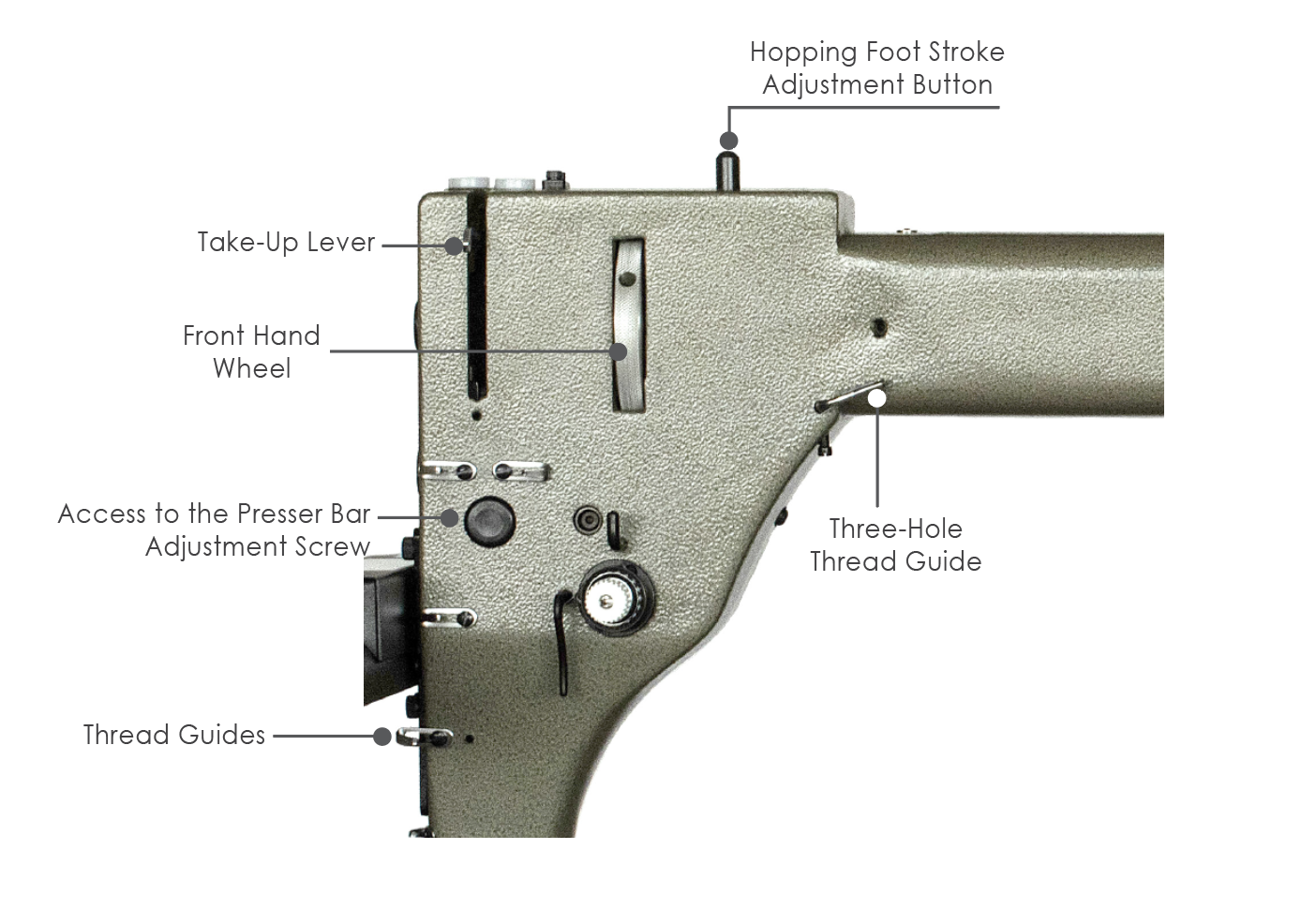

Front of the Machine

Take-Up Lever: Moves up to pull out any slack in the top thread as the stitch is completed.

Front Hand Wheel: Used to manually raise or lower the needle.

Access to the Presser Bar Adjustment Screw: Adjustments to the presser bar are made via the presser bar adjustment screw, which is covered later in the manual.

Thread Guides: Used to guide the thread during stitching to prevent thread breaks.

Three Hole Thread Guide: Used to guide the thread during stitching to prevent thread breaks. Use the first and last holes only. The first hole threaded from the bottom up and the third hole is threaded from the top down.

Hopping Foot Stroke Adjustment Button: Used to adjust the hopping foot, which is covered in a later chapter.

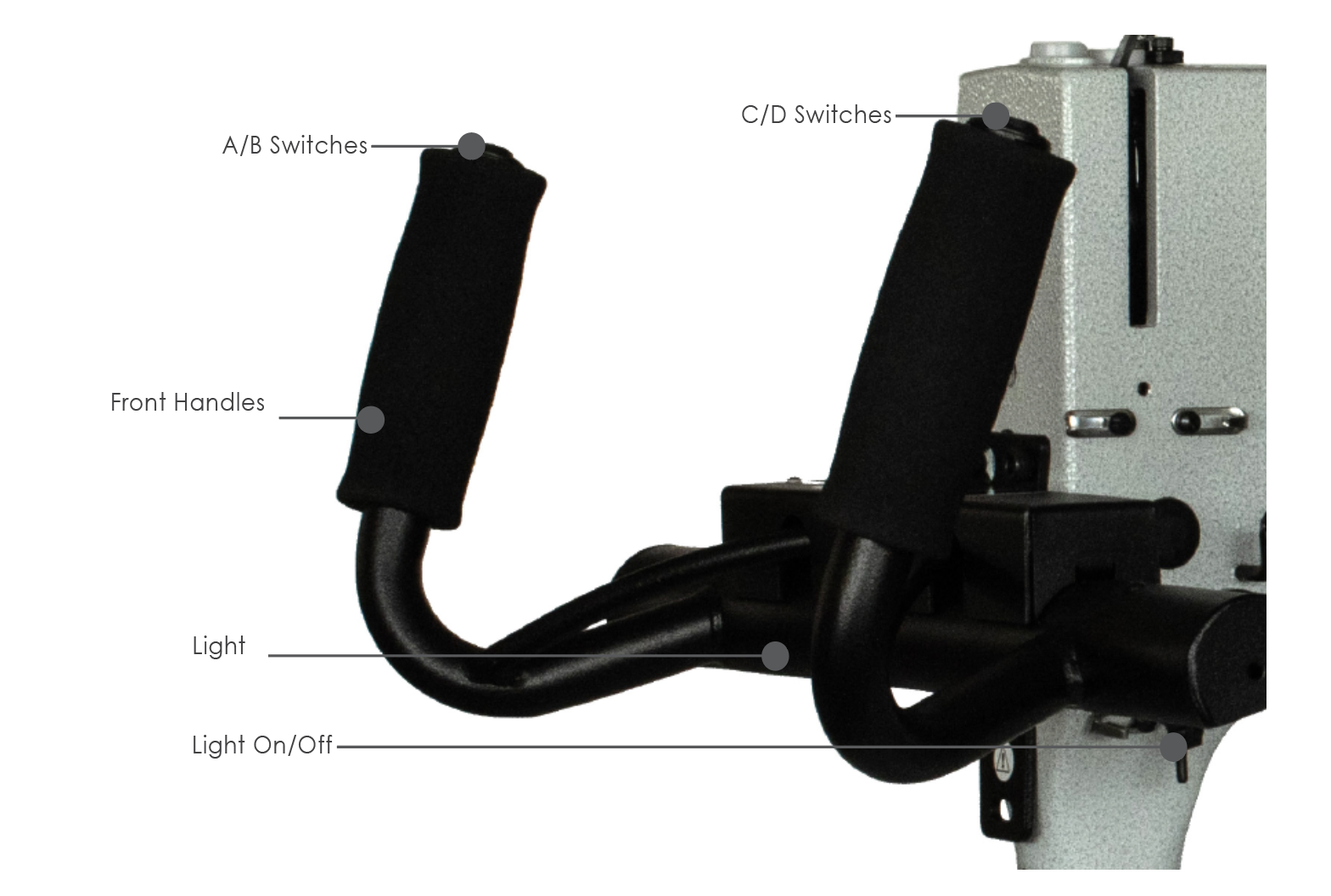

Front of the Machine

A/B and C/D Buttons: The buttons on the handles are used to control the Vision 2.0 App on the machine tablet. The buttons can be programed using the My Stitch Button feature covered later in this manual.

Front Handles: The front handles are used to move your machine manually.

Light: The light illuminates the quilting area with natural (LED) or black light (UV).

Light On/Off: Pressing the light on/off button on the light will toggle it between natural light and the black light and turn the light off.

If you have a complete Vivid Light System, you will also have a light on the throat of the machine that can be switched from natural light to black light.

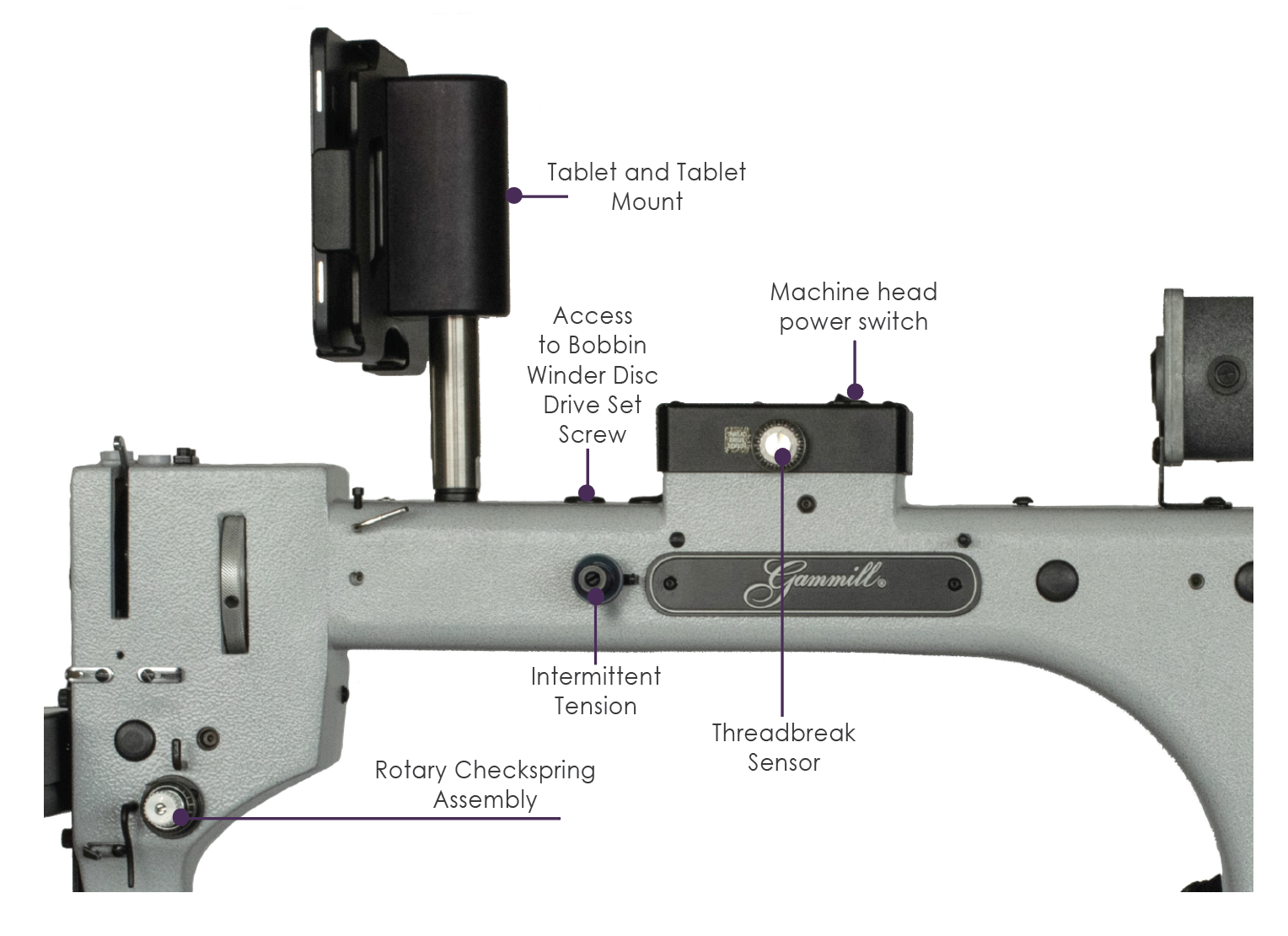

Side of the Machine

Rotary Check Spring Assembly: The housing for the check spring. The tension on the spring is set at installation. The white knob should be flush with the post and should not be turned.

Intermittent Tension: The intermittent tension is used to set the top thread tension. All adjustments to the tension are made using the intermittent tension discussed later in this manual.

Thread Break Sensor: When a thread break occurs, the thread break sensor measures thread movement and triggers an alarm when thread movement stops.

Top of the Machine

Power switches: Used to power the machine on/off.

Tablet: The tablet features the Vision 2.0 application, which allows you to communicate with your machine. This image also shows the access locations for the

Access to Bobbin Winder Disc Drive Set Screw: The access location for the bobbin winder driving disc set screw.

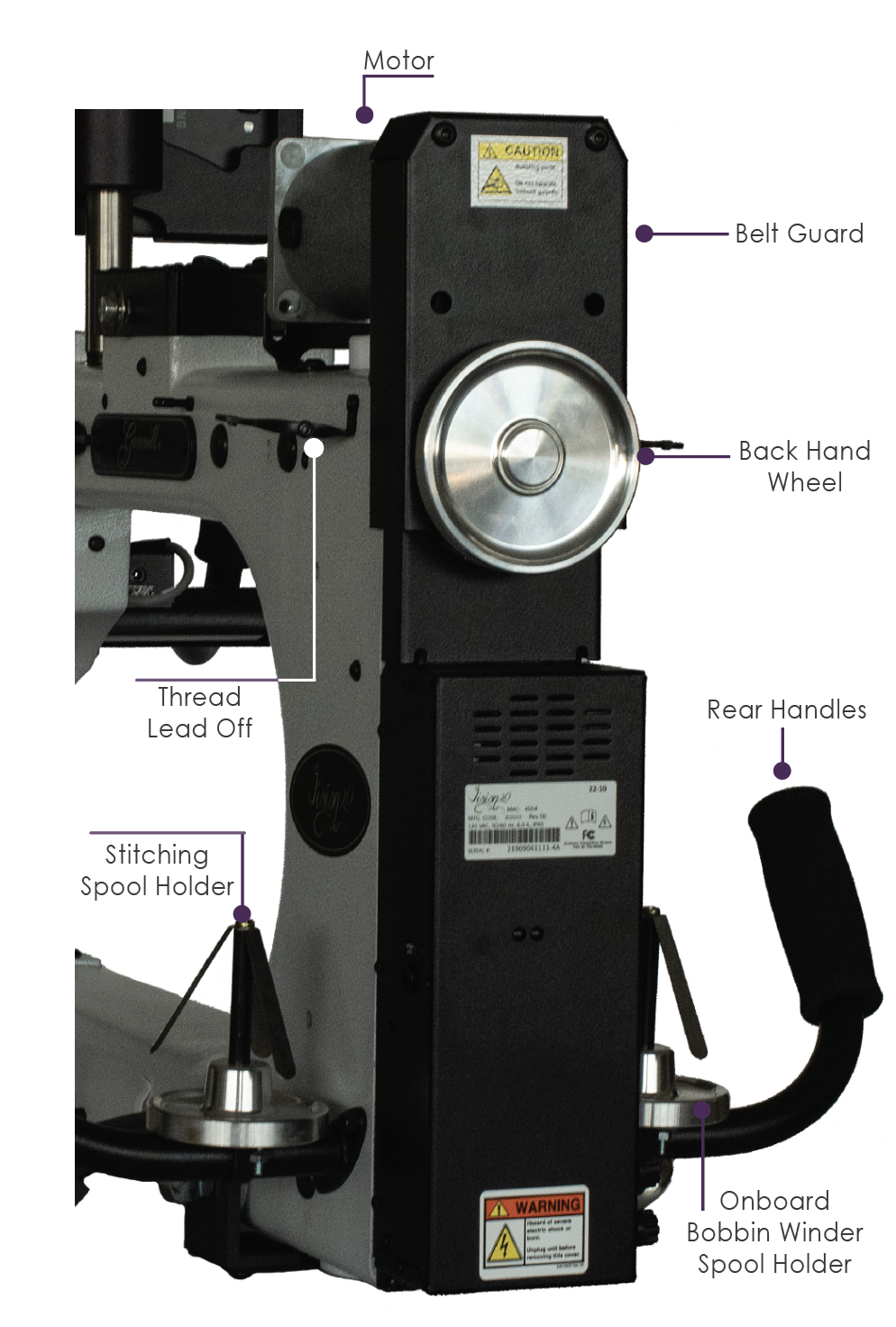

Back of the Machine

Z Motor: The Z motor powers the stitching mechanisms of the machine.

Belt Guard: The belt guard shields fingers, hair, jewelry and other objects from becoming caught in the motor belt.

Back Hand Wheel: The back hand wheel is used to manually raise and lower the needle.

Thread Lead Off: The first thread guide, the thread lead off, is located just above the cone and is threaded from the bottom up, then from back to front.

Thread Cone Holder: The thread cone holder securely holds the cone of thread to feed thread to the machine for stitching.

Rear Handles: The rear handles allow you to drive your machine from the back.

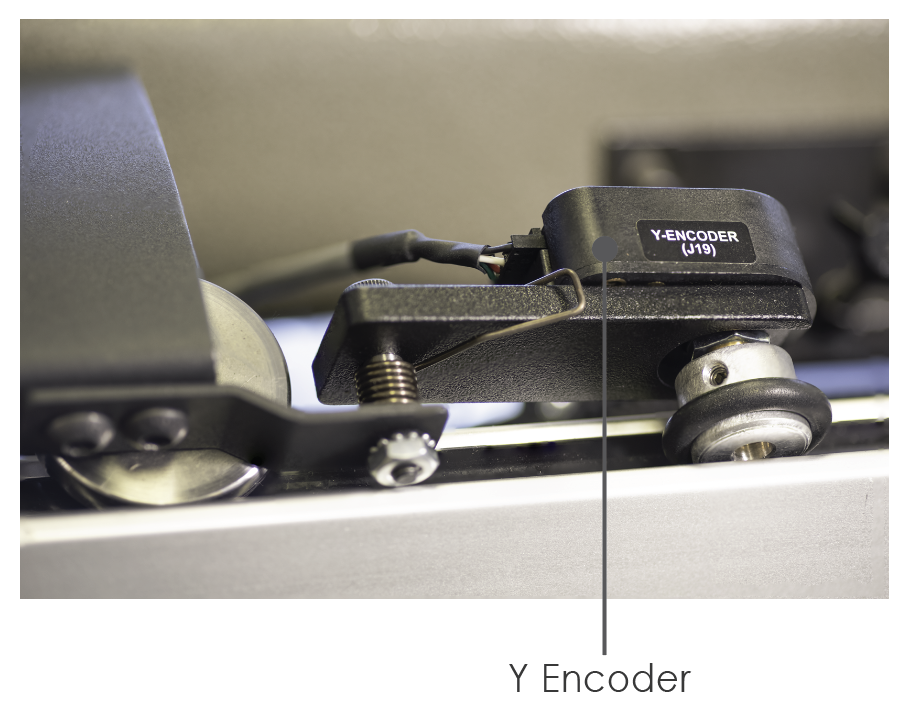

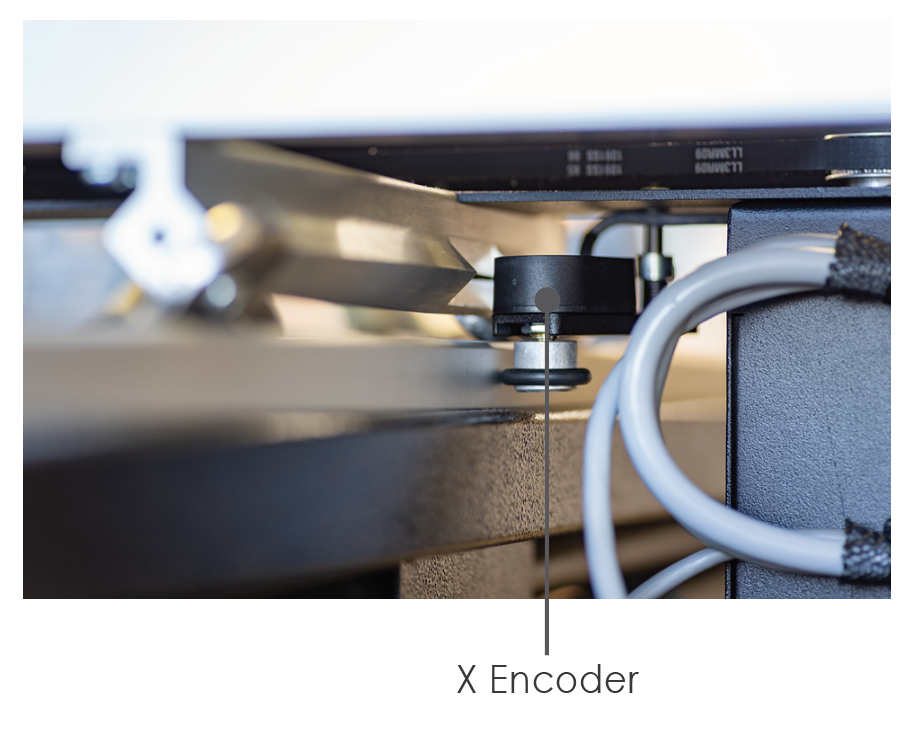

Encoders

Stitch regulation is controlled by your machine’s encoders. The Y encoder controls stitch length vertically and the X encoder controls stitch length horizontally. The encoders are located near the wheels of the crosstrack on the X and Y axises.

|

|

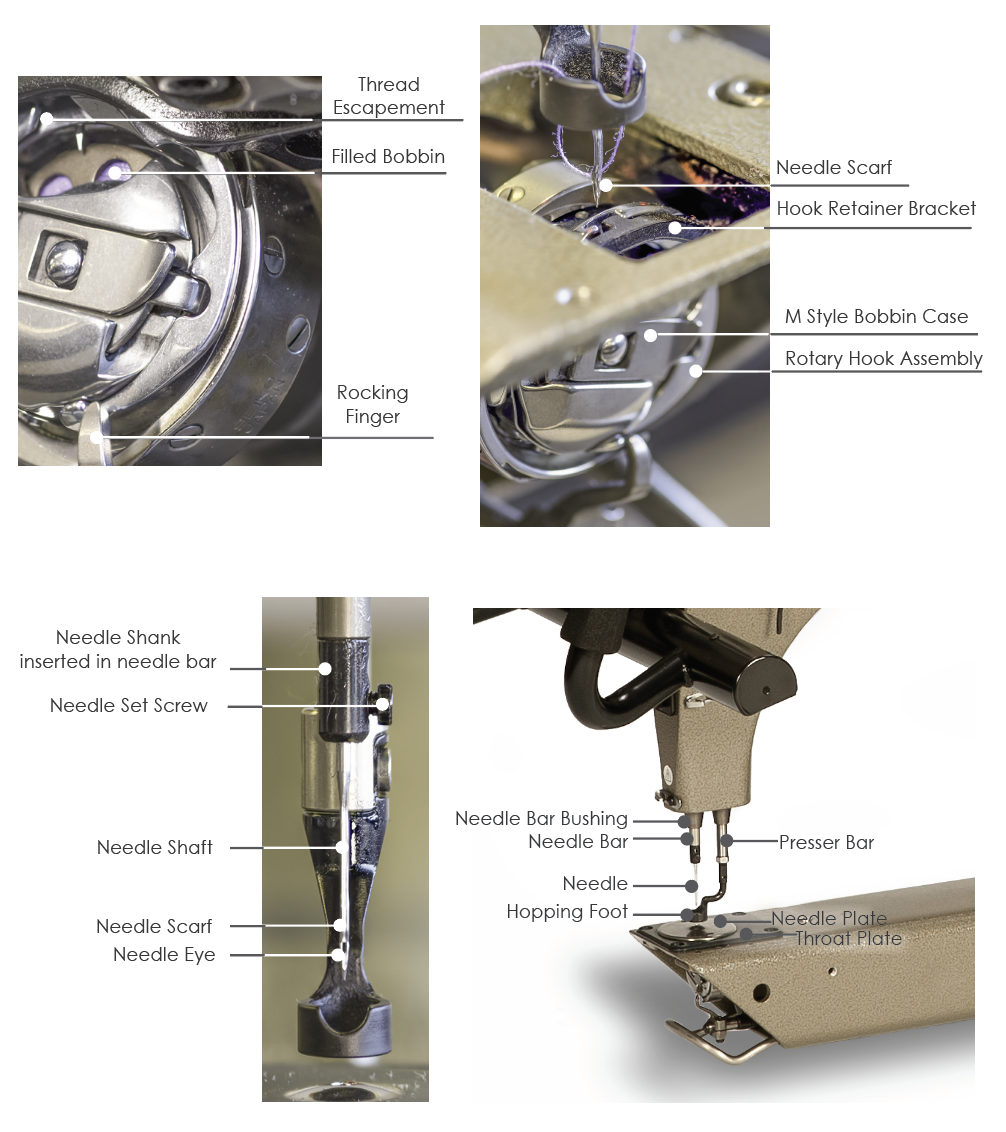

Needle Area

The Needle Area is covered in greater detail in this article.

Wheels and Crosstracks

The Crosstrack carries the machine head. Wheels move the machine head along the crosstrack. And the crosstrack moves along the Breeze Track.