Introduction to Service Commands

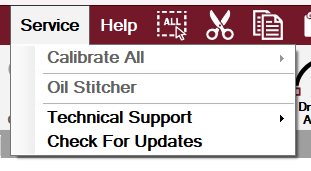

Explore the options found under the Service dropdown menu

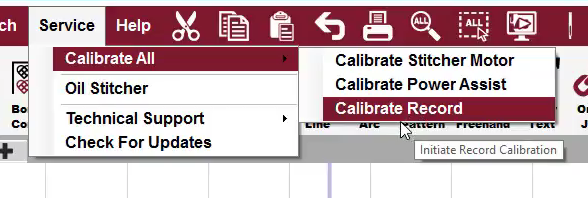

The Service Command menu lists the processes that are used for servicing. These including Calibrate All, Oil Stitcher, Technical Support, and Check for Updates.

VIDEO | Technical Support

Calibration

VIDEO | Calibrate

Calibrate checks the responsiveness of the motor, the Power Assist module and the Record module. This calibration assures you of smooth stitching, and should be performed every time the CS software is updated or other maintenance is performed.

Calibrate options include Calibrate Stitcher Motor, Calibrate Power Assist, Calibrate Record, or Calibrate All.

Calibration is easy and fast. It can be done on each module individually, or choose the option that does them all at once. The dialog boxes appear on the screen, giving instructions on what to do, and what to expect.

Once you select the type of calibration to be performed, follow the dialogue boxes for instructions.

Oil Stitcher

VIDEO | Oil Stitcher

A very small number of Gammill machines produced in the 1990s require you to perform the Oil Stitcher Routine on a regular basis to evenly distribute oil throughout the machine. The vast majority of Gammill machines do not need the to use this Oil Stitcher routine because the machine naturally distributes the oil through regular oiling and quilting. If you do have a machine that requires the specific Oil Stitcher routine, it can be found under the Service Commands menu. Click Oil Stitcher and then follow the prompts on the screen to run the routine.

Technical Support

This menu lists the options for setting defaults, defining connections, user preferences and technical troubleshooting. The User Controller Definitions are outlined below. All other options under Technical Support are used for testing purposes and should only be utilized at the instruction of a Gammill Technician or Technical Support personnel.

User Controller Definitions

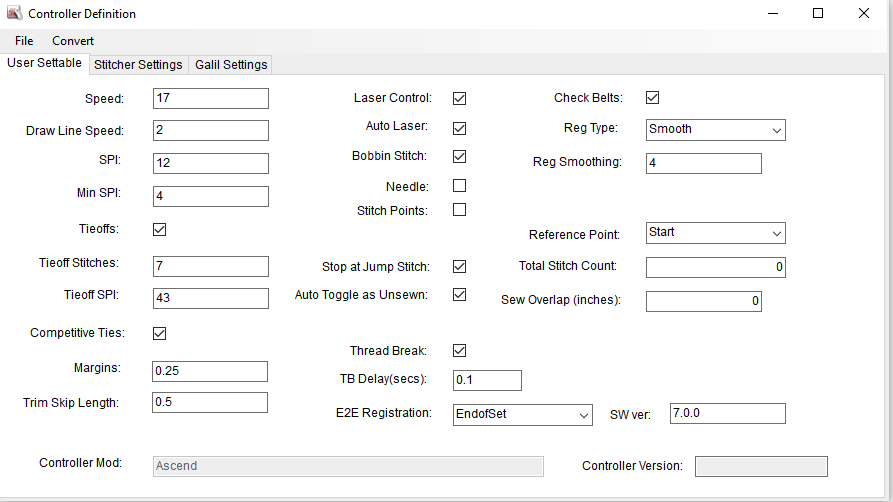

The Controller Definition Form contains the user preferences. These settings contain 'factory defaults' when the systems are first installed, but can be changed at any time.

Every quilter develops preferences over time regarding the stitching settings. These preferences are set and saved as system defaults, but can be changed to reflect what is best for a quilt.

Anytime the CS software is updated, the defaults need to be reset. It is easy to do: Here is a list of User settings, in the same order as the Controller Definition, with a definition

Speed - Speed is set to a number in the scale of 1 to 20. The default is set to 13, because that seems to be an optimum balance between pace and stitch quality.

Draw Line Speed - This speed is also a number in the scale of 1 to 20, but the default is 2, and it applies only to the Draw Line feature, which is commonly used for Stitch in the Ditch (SID). The slower speed facilitates greater accuracy.

SPI - Stitches Per Inch is the stitch length. Normal size is 12 SPI, but stitches can be as small as 1/20th of an inch, up to 4 inches in length. The very large stitches are only accessible using the Baste mode of Hand Guided Quilting.

Min SPI - This is the minimum stitches per inch (aka the largest stitches) allowed for patterns.

Tieoffs - By definition, tieoffs are tiny stitches intended to lock the thread ends and prevent the line of stitching from coming loose. If this setting is checked, CS will do tieoff stitches (standard or competitive).

- Standard tieoffs are made by taking one stitch forward and one back, in place, making a little knot.

- Competitive tieoffs are made by taking tiny stitches, all in the forward direction, along the pattern path, minimizing the visual impact.

Tieoff Stitches - This is the number of tie off stitches requested, at both the beginning and the end of a line of stitching.

Tieoff SPI - This applies to competitive tieoffs only. It is the stitch length used when doing a competitive tieoff.

Competitive Ties - By definition, competitive tieoffs are made by taking tiny stitches, all in the forward direction, along the pattern path. If this setting is checked, CS will do competitive tieoffs instead of a standard tieoffs. The length of the competitive tieoff stitches is calculated using the tieoff Stitches (default 7) times the tieoff SPI (default 43). So, CS takes 7 stitches at 43 spi, for a total length of just under 1/6 of an inch.

Margins - This is the amount of space allowed between a pattern and the boundary. In a perfect world this would be exact, but in reality it is a target; not all patterns can fit into a boundary and maintain a margin in all directions.

Trim Skip Length - This is a setting that applies to the Draw Trim process. When a pattern is trimmed to fit around an object, small pieces (smaller than this setting size) are skipped. It is assumed that these pattern segments would not detract from the design if they were missing, especially since a portion of the segment would be tieoffs.

Laser Control - This setting means the quilter can control the laser.

Auto laser - This means CS will turn the laser on/off automatically, depending on the feature.

Bobbin Stitch - This is the first stitch taken after the stitcher moves to the start of the pattern about to be quilted. If this is checked, CS will take the stitch and pause, waiting for the bobbin thread to be pulled up and the 'Continue' button to be pressed. If this is unchecked, there is no pause.

Needle - If this is checked, the needle is 'on' and will stitch. If this is unchecked, the stitcher will move along the path of the pattern but it will not stitch.

Stitch Points - This is a setting that takes an extra stitch in every point. The result is sharp, well defined points, but it does slow down the stitching somewhat.

Stop at Jump Stitch - By definition, a Jump Stitch is a break in the pattern. It might be large or small, but the 2 pattern sections are not snapped together. If this is checked, CS will pause, waiting for a 'continue' response, similar to the Bobbin Stitch. If not checked, CS will take tieoff stitches (if the settings indicate they should) and continue without stopping.

Auto Toggle as Unsewn - If this setting is on, any thread break detected will automatically change the Sewn Status for the patterns just stitched.

Thread Break - Check means the thread break sensor is on and the machine will stop if a thread break is detected. The thread break sensor is part of the top thread path. The thread wraps around it so as the machine stitches, the sensor turns. If it stops turning for a few seconds the machine assumes the thread has broken and will stop moving.

TB Delay (secs) - This setting is the adjustment for the thread break sensor. Small numbers make it very sensitive and faster to respond.

E2E Registration - This determines how the machine will prompt for registration points after the quilt has been rolled. There are 3 options to choose from (Use Start and End, Place Two Pins, User Start and End).

Check Belts - Many features depend on clicking points. When 2 consecutive click points are identical, CS will issue a warning, asking if the belts have become detached.

Reg Type - This refers to the Stitch Regulation method. The three choices (Original, Smooth and Plus) each handle just a little differently.

Reg Smoothing - This also refers to the stitch regulation, particularly how curves are stitched. This setting changes the smoothing algorithm slightly, when the machine moves fast.

Reference Point - This is used when placing Repeat Patterns. The default is set here, but can be changed at the time the Repeat Pattern Feature is used. This is the normally preferred method (Upper Left, Upper Right, Lower Right, Lower Left, Start, End, Center).

Total Stitch Count - This is a running count of the number of stitches taken since the software was installed.

Sew Overlap (inches) - Sometimes block patterns (where the start point and the end point are the same) look better if the stitches overlap, and this setting will allow that.

Stand Alone Mode - Also known as SAM, this box is checked when the computer is running CS but the controller is not attached, connected or engaged.

SAM Controller # - This is the controller number for the Stitcher. By entering it here, CS can check the encryption of patterns without needing the controller attached and running.

Controller Mod - This is the model letter/number of the controller that controls the stitching process.

Controller Version - This is the version of software currently running the controller.

Making Changes to Controller Definitions

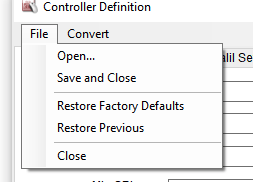

Once changes are made to the user Controller Definitions, you can click file, save and close to activate the settings. You can also Restore Previous settings or Restore Factory Defaults.

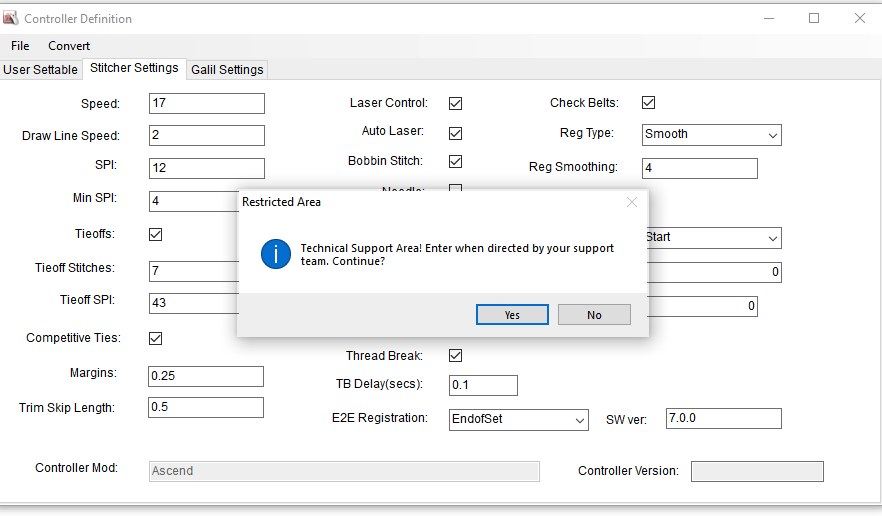

Stitcher Settings and Galil Settings should only be accessed when directed by a Gammill Technician or Technical Support Team Member.

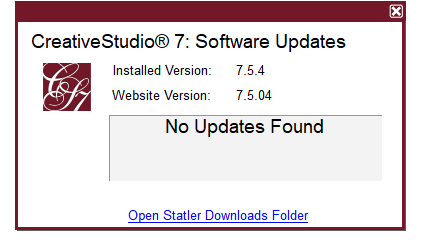

Check for Updates

Gammill is continuously striving to produce the highest quality software for our quilting family and therefore provides regular updates to CreativeStudio. If your computer is connected to the Internet, you will receive a prompt whenever an update is available.A message appears asking if the updates are to be installed at this time. Follow the prompts to update the software. The release notes will summarize what has changed. If special instructions are required, they will be documented there.

You can also check for updates under Service to ensure you are using the latest version of software.

When an internet connection is not available, the software must be downloaded to a different (non-Statler) computer.

Continue to download the software, then copy it to a thumb drive to transfer it to your genuine Statler computer. The install process is described in this section.

Go ahead and use the software on a non-Statler computer, (in Stand Alone Mode - SAM) to create projects and/or patterns. SAM was intended to help quilters be more productive by allowing design work to be done while the Stitcher is stitching.